Together for complete lines

For many years, IRIS and Heye have together been supplying inspection lines for glass container factories worldwide. We are both specialists in our field : IRIS in camera inspection machines, Heye in check inspection machines. This complementary partnership has today become a cold end commercial alliance with added value where intelligent software is combined with a robust mechanics. We bring a collective expertise to your cold end.

Since 2002, IRIS has designed, developed and manufactured intelligent inspection solutions for glass containers. The company offers precise and innovative inspection machines with reduced dependence on the human factor for your increased productivity, quality and efficiency. IRIS is a team of passionate engineers, mastering the entire production of machines from ideas and concepts, to the production of CPU boards and on-site installation.

Based in Obernkirchen, Germany, Heye International is one of the foremost suppliers of production technology, high performance equipment and know-how for the container glass industry worldwide. Our mechanical engineering has set the standard in the industry for more than 50 years. The industry expertise, attitude and enthusiasm of Heye International employees conforms to the motto “WE ARE GLASS PEOPLE”.

EVOLUTION 12 NEO is an intelligent sidewall inspection machine with 12 HD cameras. Thanks to its unique optical design, EVOLUTION 12 NEO provides full body coverage. Equipped with a 21.5’’ touchscreen, these machines offer a full display of 12 to 16 images. The latest generation cameras take sharper and more accurate images improving discrimination between different types of defects (eg small stones and blisters) A powerful processing unit with innovative design and reduced maintenance cost offers a platform for new inspection intelligence.

Advantages at a glance

EVOLUTION 5 NEO is a fully automatic machine for base, finish, base stress inspection and mould number reading. It is totally modular and can be equipped with between one and 5 HD cameras to fit your inspection needs. A new mechanical design provides better access to all inspection stations and saves set-up. The latest generation LED ensures lighting from several angles to obtain a better image for inspection. Equipped with 21.5’’ deported touch screen with a user-friendly interface, EVOLUTION NEO offers quick and easy job change and inspection of round and non-round containers.

Advantages at a glance

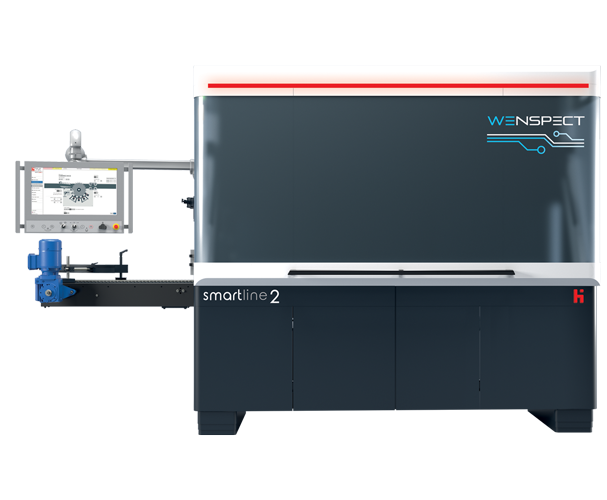

Heye SmartLine 2 is the new generation of Heye’s starwheel inspection machine series. The SmartLine series sets the standard in reliability and robustness. The user interface has been improved and makes job changes as easy as possible. Both, the mechanical design and the control unit are extremely reliable and easy to operate. The large hood gives maximum access to the working space, reducing job change times to the absolute minimum. The latest non-contact inspection features are integrated, as well as a self-learning system for camera-based check detection.

Advantages at a glance

For many years, IRIS and Heye have together been supplying inspection lines for glass container factories worldwide. We are both specialists in our field : IRIS in camera inspection machines, Heye in check inspection machines. This complementary partnership has today become a cold end commercial alliance with added value where intelligent software is combined with a robust mechanics. We bring a collective expertise to your cold end.

contact@we-nspect.com

www.we-nspect.com

FRANCE

IRIS Inspection machines

14 rue du 35e Régiment d’Aviation

69500 BRON - France

Phone: +33 (0)4 72 78 35 27

Fax: +33 (0)4 72 78 35 07

GERMANY

Heye International GmbH

Lohplatz 1

31683 Obernkirchen - Germany

Phone: +49 5724 26-0

Fax: +49 5724 26539